pistonring climper

gap

gap gauge.

<H1 id=ctl00_ctl08_ctl00_lblT itle class="font_sup color_2 bold" itxtBad="1">Piston Ring Prep - Ringing In The Power

<H1 id=ctl00_ctl08_ctl00_lblT itle class="font_sup color_2 bold" itxtBad="1">Piston Ring Prep - Ringing In The Power

|

Tweet

<SCRIPT type=text/javascript itxtBad="1"> $(function() { var fbLike = '<iframe src="http://www.facebook.com/plugins/like.php?href=http://www.circletrack.com/enginetech/ctrp_0808_piston_ring_pre p/index.html&layout=standar d&show_faces=false&width= 260&action=like&colorsche me=light&height=26" scrolling="no" frameborder="0" style="border:none; overflow:hidden; width:260px;height:26px;" allowTransparency="true"> </iframe>'; $('#facebook-like').html(fbLike); $.getScript('http://platform.twitter.com/widgets.js'); }); </SCRIPT>

After filing your ring and...

read full caption

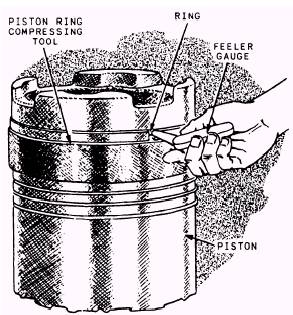

After filing your ring and before trial fitting inside the cylinder bore, take a moment to knock the burr off of the outside edge of the ring. If this isn't done it can throw off your gap measurement.

Dorton uses a powered ring filer, but a more traditional crank-style ring filer is a more economical option for those of us who aren't building engines for a living. No matter what you use, you must be careful to only make small cuts on the rings because you can't put material back on. Also, be prepared to put in a little practice with a couple of old rings before you can reliably make smooth, perpendicular cuts on the rings.

The size of the ring gap necessary varies by the amount of heat generated and which ring you are talking about. But the variables are mostly limited to whether you are running naturally aspirated or using a turbocharger. Fortunately, for stock car racing, there isn't as much variance whether we are talking about Street Stocks or an ARCA engine, so the following recommendations hold true no matter what division you race.

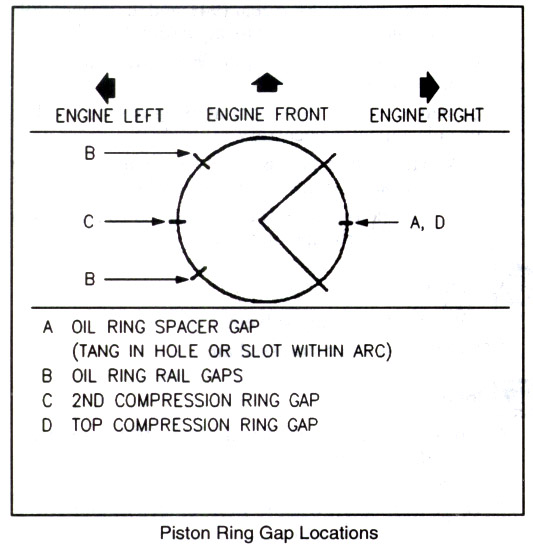

Because the top ring sees the most heat, it requires the largest gap. Dorton says that for anything with a bore between 4.00 and 4.100 inches, a 0.022-inch gap should work fine. In fact, Dorton says he has experimented with gaps everywhere between 0.016 and 0.030 inch on the dyno on several different styles of engines and seen no real difference in terms of power.

Insert the ring into the cylinder...

read full caption

Insert the ring into the cylinder and then use a ring-squaring tool to make sure it is perpendicular to the centerline of the cylinder bore. If you don't have a squaring tool, you can use a piston that has the top ring installed. Simply install the ring in the top of the bore and then use the piston to push it into the bore until the ring installed on the piston contacts the deck of the block all the way around.

On the same piston, the second ring should be gapped between 0.016 and 0.020 inch. Less gap is necessary because the second ring is protected from hot combustion gasses by the top ring, but you still don't want it too tight to eliminate the possibility of ring flutter on the top ring.

Finally, Dorton recommends going in the opposite direction for the oil ring. In order to get maximum oil control, the gaps in the oil rails need to be as tight as absolutely possible. Dorton says that as long as you can fit the rings inside the cylinder bore without them butting then you will be fine, but a practical gap should be between 0.006 and 0.008 inch.

Rings are critical for proper engine operation, but they also cost you some power. The movement of the rings against the cylinder walls creates drag, and any portion of that drag you can eliminate while still maintaining proper combustion in the chambers, the better off you will be. To get a better idea of how much power we are talking about, Dorton mentions a test he did several years ago with a race engine. After dyno'ing the engine to determine a baseline, he says he pulled the heads, dropped the oil pan, and removed all the pistons and rods. He pulled the second ring off of all the pistons, rebuilt the motor right there on the dyno stand, and fired the engine back up. With the 0.060-inch second ring removed from all eight pistons the engine gained 5 hp over its 400hp baseline!

After the ring is correctly...

read full caption

After the ring is correctly gapped, use a honing stone to knock the burr off of the edges of the ring. Make sure only to knock the burr off and not round the edges of the ring as you can see here. This will kill the ring's ability to seal off the combustion chamber.

This is why most piston manufacturers now offer race-quality pistons with ring lands designed for thinner rings. The reduced surface area contacting the cylinder walls creates less drag. Where most performance ring packages used to be 1/16, 1/16, and 3/16, new metric-based rings sized at 1.2, 1.2 and 3 millimeters are gaining popularity.

One drawback is that low-tension rings simply do not do as good a job of scraping oil off of the cylinder walls. Fortunately, the solution is to use pistons with gas ports. Gas ports are simply slots drilled into the top of the upper ring land that allows combustion pressure to get behind the ring. This pressure from combustion pushes the ring down against the bottom of the piston's ring land and out against the cylinder wall, improving cylinder sealing. Then, on the exhaust stroke when the pressure is reduced, the friction between the ring and the cylinder wall is greatly reduced.

Prev | 1 | 2 | 3 | Next

G IFT4U

</H1>